Innovate Customer-Facing Processes Throughout Your Organization

Just as a pit crew at a racetrack changes tires and refuels the car with the utmost efficiency and consistency, letting their driver get back into the race as quickly as possible, security companies should implement strong processes and operations to eliminate inconsistencies and better serve customers. Mike Jagger, Founder and CEO of Provident Security Corporation, knows this firsthand: his company promises a five-minute response time to every alarm, which can involve logistical challenges, since they secure more than 20,000 house keys in British Columbia. He spoke to ESX attendees on how to implement innovative processes to help their companies run more smoothly and achieve greater success – and how looking at business models outside of security can inspire new approaches.

Understanding Value

Working with intention has framed Provident’s operational strategies. “There’s always more work to be done and it can’t be perfect, but we recognize there’s always some place we can improve. The worst answer somebody can have for something is ‘This is just the way we’ve always done it,’” Jagger said.

Provident has taken notes from Mrs. Fields Cookies on operations. Mrs. Fields evaluated sales and inventory data over time to create processes that required very little decision-making by store employees. Since Mrs. Fields’ brand depended on young, enthusiastic team members as the “face” of their stores, these processes let those team members prepare for each day’s sales and operations without having to have training in strategy or management. Empowering employees to do their work properly and efficiently lets them focus on what they are good at, whether it be selling cookies or installing security equipment.

Toyota is a company that has long been lauded for operational efficiencies, and their focus on waste reduction can be carried over into the security industry. Waste is not necessarily tangible; waste can be accumulated through processes that don’t add value. Viewing waste as an opportunity to enact change has proven to be powerful for Provident, who audited every element of their business and assessed which areas were most valuable to customers. For example, customers don’t tend to care as much about brand names of products as they do about customer service. Value doesn’t necessarily correlate to cost: having a central station, though expensive, “is something clients will pay a premium for because they value it specifically,” Jagger explained. In addition, the value of automating processes and investing in specific hardware is measured based on how it improved customer support.

Evaluating Processes

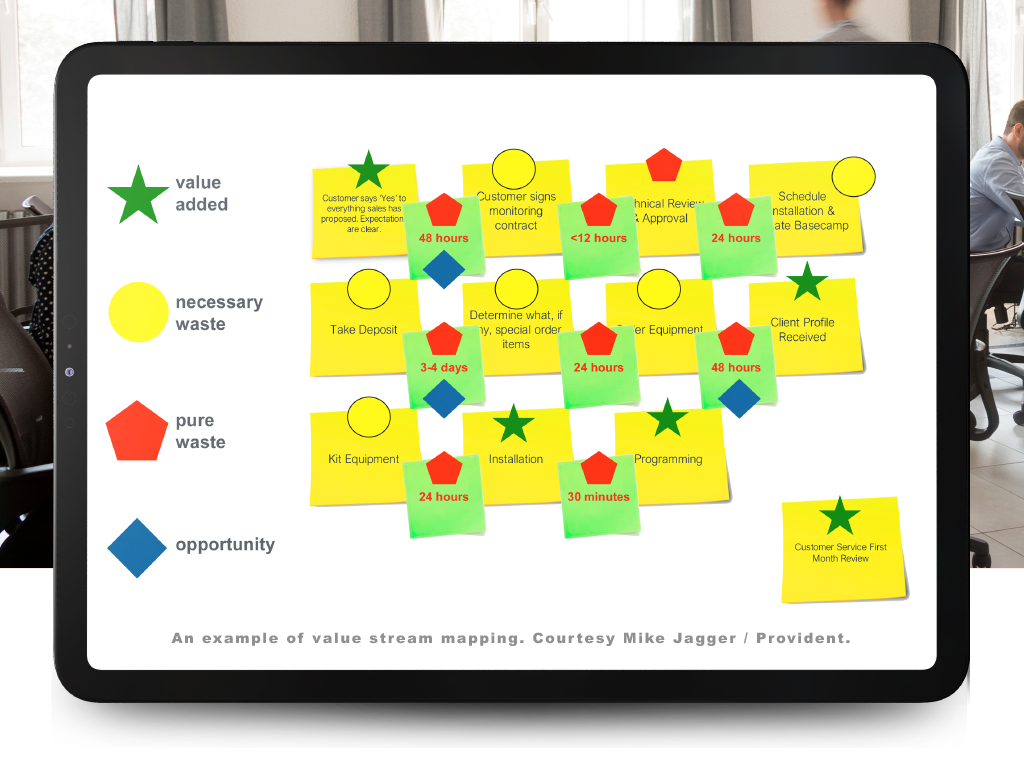

Value stream mapping is a technique to identify which part of each process is the most valuable – that is, whether a customer would pay for it. This can be achieved by laying out how many steps take place in a process, how much time each step takes, and evaluating whether they’re in the most efficient order. Most importantly, denote which parts are necessary waste (such as the customer signing a contract), pure waste, value adds, or opportunities. Doing this visually – such as filling a wall with color-coded Post-It notes for each step – helps clarify the process as a whole and diagnose potential pain points. “No matter how many steps there are, there are actually very few true steps where value is added,” Jagger remarked, but pinpointing value as well as areas for opportunity helps reduce or eliminate wasted time.

Doing post-mortems are another critical step in preventing problems from recurring. “We do a constant autopsy to dig into what happened in each job and look into what is the earliest possible time we could have known that this [issue] would happen,” Jagger commented. “Most of the experience we’ve had is that the hard work for us has been figuring out how to ask better questions…What are the crucial questions we need to ask and have answers to at the very beginning? What are we tracking that allows us to eliminate the risk of surprises down the line? Continually reframing questions and asking them in a thoughtful, specific way will give complete clarity.” Having structured, uniform data is also key in creating consistencies in reporting, ensuring that all processes are being appraised against a baseline.